If you’ve ever weighed a package, calculated an expected shipping cost, and then received an invoice that was significantly higher, you’re not alone. This frustrating experience catches thousands of ecommerce sellers off guard every month, eating into profit margins and creating confusion about carrier billing practices.

The culprit? Dimensional weight pricing—a billing method that has become the industry standard for UPS, FedEx, USPS, and virtually every major carrier operating in 2026.

In this guide, we’ll break down exactly why your shipping bill doesn’t match your scale, how carriers calculate what you actually owe, and actionable steps to stop overpaying immediately.

The Hidden Pricing Model: Dimensional Weight Explained

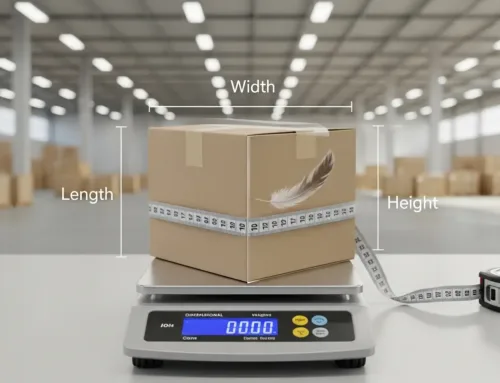

When you place a package on a scale, you get the actual weight—the physical mass of your product plus packaging materials. Simple enough.

But carriers don’t just transport weight. They transport space. A delivery truck can only fit so many packages, regardless of how light each one is. This is where dimensional weight (also called DIM weight or volumetric weight) comes into play.

Dimensional weight is a pricing technique that reflects the amount of space a package occupies relative to its actual weight. It was introduced because shippers were sending larger boxes with minimal contents, taking up valuable cargo space while paying rates based on light actual weights.

The Bottom Line: Carriers charge you based on whichever is greater—the actual weight or the dimensional weight. This higher value becomes your billable weight.

How Dimensional Weight Is Calculated

The formula for calculating dimensional weight is straightforward:

Dimensional Weight = (Length × Width × Height) ÷ DIM Factor

Here’s what you need to know:

- Measurements are taken in inches (for domestic U.S. shipments)

- Round up each dimension to the nearest whole inch

- Divide the cubic volume by the carrier’s DIM factor

Understanding DIM Factors by Carrier (2026)

Different carriers use different DIM factors, which significantly impacts your billable weight:

| Carrier | DIM Factor | Notes |

| UPS | 139 (daily rates) / 166 (retail rates) | Applies to all Ground packages |

| FedEx | 139 | Standard for domestic services |

| USPS | 166 | Only applies to packages over 1 cubic foot (1,728 in³) for Zones 5+ |

What does the DIM factor mean? A lower DIM factor (like 139) results in a higher dimensional weight, meaning you’ll pay more for the same box compared to a carrier using 166.

Real-World Example

Let’s say you’re shipping a box that measures 18″ × 14″ × 10″ and weighs 5 lbs.

Step 1: Calculate the cubic volume 18 × 14 × 10 = 2,520 cubic inches

Step 2: Calculate dimensional weight (using DIM factor 139)2,520 ÷ 139 = 18.1 lbs (rounded up to 19 lbs)

Step 3: Determine billable weight – Actual weight: 5 lbs – Dimensional weight: 19 lbs – Billable weight: 19 lbs

In this case, you’d pay for a 19-lb package even though it only weighs 5 lbs on the scale. That’s nearly a 4x difference between what you expected and what you’re charged.

Want to check your own packages? Use our free Dimensional Weight Calculator to see exactly what you’ll be billed before you ship.

Why This Matters for Ecommerce Sellers

If you’re running an ecommerce fulfillment operation, dimensional weight pricing can make or break your profit margins. Here’s why:

1. Bulky Products Get Penalized

Products like pillows, lampshades, pet beds, and plastic storage containers are notorious for triggering high DIM weights. These items are light but take up substantial space in delivery vehicles.

2. Oversized Packaging Compounds the Problem

Using a box that’s too large for your product doesn’t just waste packing materials—it actively increases your shipping costs. Every extra inch of empty space translates to a higher dimensional weight.

3. Carrier Audits Are Getting Stricter

In 2026, carriers like UPS and FedEx use advanced scanning technology to verify package dimensions. If your declared dimensions don’t match the actual measurements, you’ll receive adjustment fees—sometimes with penalties on top.

How to Stop Overpaying on Shipping

Understanding dimensional weight is only half the battle. Here’s how to take action:

1. Right-Size Your Packaging

The single most effective way to reduce shipping costs is to use the smallest box possible that safely protects your product. Consider:

- Custom box sizes tailored to your bestselling products

- Poly mailers for soft goods that don’t need rigid protection

- Padded flat-rate envelopes for small, high-value items

Our packaging solutions team can help you identify the optimal box sizes for your product catalog.

2. Calculate Before You Ship

Never assume your actual weight determines your shipping cost. Use a dimensional weight calculator for every new product or box configuration before committing to a shipping method.

3. Compare Carrier DIM Factors

Remember that USPS uses a more favorable DIM factor of 166compared to UPS and FedEx’s 139. For bulky, lightweight items, USPS Priority Mail can offer significant savings—especially for zones 1-4 where DIM weight doesn’t apply.

4. Negotiate Better Rates

High-volume shippers can often negotiate custom DIM factors with carriers. If you’re shipping thousands of packages monthly, it’s worth exploring carrier negotiations or working with a 3PL fulfillment partner who already has preferential rates.

5. Partner with a Fulfillment Expert

Managing packaging optimization, carrier selection, and dimensional weight calculations across hundreds of SKUs is complex. A professional fulfillment center handles this automatically, ensuring every package ships at the lowest possible cost.

2026 Carrier Updates You Should Know

Shipping carriers regularly adjust their policies, and staying current is essential for accurate cost projections:

- UPS and FedEx now round each dimension up to the nearest whole inch before calculating DIM weight (implemented August 2025)

- USPS continues to apply DIM weight only to packages exceeding 1 cubic foot for Zones 5-9

- All major carriers have increased their dimensional weight scrutiny with automated measurement systems at sorting facilities

These changes make it more important than ever to optimize your fulfillment strategy for dimensional efficiency.

Common Products That Trigger DIM Weight Surcharges

Certain product categories almost always result in dimensional weight exceeding actual weight:

| Product Category | Typical DIM Weight Issue |

| Home décor (throw blankets, pillows) | Light but bulky |

| Pet supplies (beds, carriers) | Large volume, minimal weight |

| Sporting goods (helmets, protective gear) | Rigid packaging requirements |

| Electronics (monitors, TVs) | Box size driven by product dimensions |

| Apparel in retail boxes | Gift packaging adds volume |

If you sell products in these categories, dimensional weight optimization should be a core part of your warehousing and distribution strategy.

Take Control of Your Shipping Costs Today

Dimensional weight pricing isn’t going away—it’s the standard across all major carriers and will only become more strictly enforced. The sellers who thrive are those who understand the system and optimize accordingly.

Your next steps:

- Audit your current packaging — Are you using boxes larger than necessary?

- Calculate your DIM weights — Use our Dimensional Weight Calculator to identify which products are costing you the most

- Compare carrier options — Different DIM factors mean different costs for the same package

- Consider professional fulfillment — ShipCore’s fulfillment services include packaging optimization as standard

Still have questions about dimensional weight or need help optimizing your shipping strategy? Contact our team for a free consultation.

Frequently Asked Questions

What is billable weight?

Billable weight is the weight used by carriers to calculate your shipping charges. It’s the greater of your package’s actual weight or its dimensional weight.

Why do carriers use dimensional weight?

Carriers use dimensional weight because they have limited space in their vehicles. A large, lightweight package takes up cargo room that could otherwise hold multiple smaller packages. DIM weight ensures carriers are compensated for the space occupied, not just the physical weight transported.

How can I reduce my dimensional weight?

The most effective strategies include: using smaller boxes, switching to poly mailers when appropriate, eliminating excess void fill, and considering custom packaging for high-volume SKUs. Working with a fulfillment partner who optimizes packaging automatically can also significantly reduce DIM weight across your catalog.

Does USPS use dimensional weight?

Yes, but with limitations. USPS applies dimensional weight only to packages that exceed 1 cubic foot (1,728 cubic inches) and ship to Zones 5-9. USPS also uses a more favorable DIM factor of 166 compared to UPS and FedEx’s 139.

What is the DIM factor for UPS in 2026?

UPS uses a DIM factor of 139 for daily/contract rates and 166 for retail rates. The lower factor (139) results in higher dimensional weights and is applied to most business shipments.

Ready to see exactly what you should be paying? Calculate your dimensional weight now and take control of your shipping costs.