Your product is perfect. Your customers love it. But your shipping costs keep climbing, and you’re not sure why.

Here’s the truth: most ecommerce brands are paying 15-30% more on shipping than they need to—not because of carrier rates, but because of how they package their products.

The good news? You can dramatically reduce your shipping expenses without redesigning a single product. This guide walks through five proven packaging optimization strategies that leading brands use to protect their margins in 2026.

Strategy #1: Conduct a Packaging Audit (And Find the Money You’re Leaving on the Table)

Before making any changes, you need to understand where you’re bleeding money. A packaging audit reveals exactly which SKUs are costing you the most—and why.

How to Run a Packaging Audit

Step 1: Pull Your Shipping Data

Export the last 90 days of shipments. For each order, you’ll need: – Product SKU – Box dimensions used – Actual weight – Carrier and service level – Amount billed

Step 2: Calculate the DIM Gap

For each shipment, compare what you should be paying (based on actual weight) versus what you actually paid (often based on dimensional weight). The difference is your DIM gap.

Use our Dimensional Weight Calculator to check any package’s billable weight instantly.

Step 3: Identify Your Worst Offenders

Sort by the largest DIM gaps. You’ll typically find that 20% of your SKUs drive 80% of your excess shipping costs. These are your priority targets for optimization.

What a Packaging Audit Reveals

| Common Finding | Typical Cause | Potential Savings |

| Same box used for all orders | “One-size-fits-all” mentality | 15-25% per package |

| Products swimming in void fill | Box too large for contents | 10-20% per package |

| Light items in heavy-duty boxes | Over-engineered protection | 5-15% per package |

| Gift sets in retail packaging + shipping box | Double boxing | 20-30% per package |

A professional fulfillment partner can run this analysis automatically across your entire catalog, identifying optimization opportunities you’d never spot manually.

Strategy #2: Build a Right-Sized Box Library

The fastest path to lower shipping costs is eliminating empty space. That means having the right box for every product combination—not forcing products into whatever boxes you have on hand.

The Box Library Approach

Instead of stocking 2-3 generic box sizes, develop a curated library of 5-8 sizes optimized for your bestselling products and common order combinations.

Here’s how to build yours:

- Analyze your top 50 SKUs — Measure each product’s packed dimensions (with protective materials)

- Group by size ranges — Cluster products that fit the same box

- Account for kitting — Identify common multi-item orders and size boxes accordingly

- Add 1″ tolerance — Allow for protective wrapping without forcing products

Sample Box Library for an Apparel Brand

| Box Name | Interior Dimensions | Best For |

| Tee Single | 10″ × 8″ × 2″ | 1-2 folded t-shirts |

| Tee Multi | 12″ × 10″ × 4″ | 3-5 t-shirts or 1-2 hoodies |

| Accessory | 8″ × 6″ × 2″ | Hats, belts, small items |

| Outerwear | 16″ × 12″ × 4″ | Jackets, coats |

| Bundle Box | 14″ × 12″ × 6″ | Large multi-item orders |

Cost Impact of Right-Sizing

Industry data shows that switching to right-sized corrugated boxes can: – Reduce freight costs by 7% – Cut material spending by 20% – Lower damage claims by 30-40%

When products fit snugly, they don’t shift during transit—reducing both dimensional weight and breakage.

Strategy #3: Replace Boxes With Flexible Packaging (Where Possible)

Not every product needs a rigid box. For many items, switching to flexible packaging like poly mailers, padded envelopes, or paper mailers can slash shipping costs dramatically.

Poly Mailers: The Numbers

| Packaging Type | Approximate Cost | Shipping Weight Impact |

| Cardboard box (12″ × 10″ × 4″) | ~$0.78/unit | Adds 8-12 oz |

| Poly mailer (12″ × 15″) | ~$0.13/unit | Adds <1 oz |

| Padded mailer (10″ × 13″) | ~$0.25/unit | Adds 1-2 oz |

That’s an 83% reduction in packaging cost plus additional shipping savings from reduced weight and dimensions.

When Flexible Packaging Works

✅ Ideal candidates: – Apparel (t-shirts, pants, dresses, accessories) – Soft home goods (linens, towels, bedding) – Non-fragile accessories (bags, belts, wallets) – Books and printed materials – Soft toys and plush items

❌ Keep using boxes for: – Fragile or breakable items – Products requiring visual presentation (premium unboxing) – Items needing structural protection – Electronics and precision products

Hybrid Approaches

Many brands use flexible packaging as the primary shipper with targeted protection where needed: – Wrap fragile components in bubble before placing in poly mailer – Use rigid inserts for items needing structure – Ship related items together—soft items cushion harder ones

Your pick and pack fulfillment process should have clear guidelines on which packaging type to use for each product.

Strategy #4: Rethink Your Void Fill Strategy

Empty space in a box does double damage: it increases dimensional weight (higher shipping costs) and allows products to shift (more damage claims). But the solution isn’t just cramming in more packing peanuts.

The True Cost of Void Fill

Traditional void fill materials add up quickly:

| Void Fill Type | Cost Per Cubic Foot | Environmental Impact |

| Styrofoam peanuts | $0.50-$1.00 | Non-biodegradable, landfill waste |

| Plastic bubble wrap | $0.75-$1.25 | Recyclable but rarely recycled |

| Plastic air pillows | $0.40-$0.80 | Takes 500+ years to decompose |

Beyond the material cost, excessive void fill signals a deeper problem: you’re using the wrong box size.

Better Alternatives

Paper-Based Options: – Kraft paper — Cost-effective, recyclable, can be crumpled to fill voids – Crinkle paper — Shredded and textured for cushioning, visually appealing – PaperBubble — Paper-based bubble wrap alternative, same protection without plastic

Minimalist Approaches: – Tissue paper wrapping — Works for durable items, adds premium feel – No void fill — If the box is right-sized, you may not need any

The Real Solution: Less Void, Not Better Fill

The goal isn’t finding cheaper or greener void fill—it’s eliminating the need for it.

When a box is properly sized for its contents, products are naturally secured with minimal movement. Every inch of void space you eliminate reduces: – Material costs – Labor time (someone has to add that fill) – Dimensional weight – Damage claims

This is why professional warehousing operations invest in diverse box inventories—the upfront cost of stocking more sizes pays for itself many times over.

Strategy #5: Pre-Calculate Before You Commit

The costliest packaging mistakes happen early—when you’re sourcing products, designing retail packaging, or selecting box sizes. Once you’ve ordered 10,000 units of product in retail boxes, it’s too late to optimize.

The Pre-Shipping Calculation Workflow

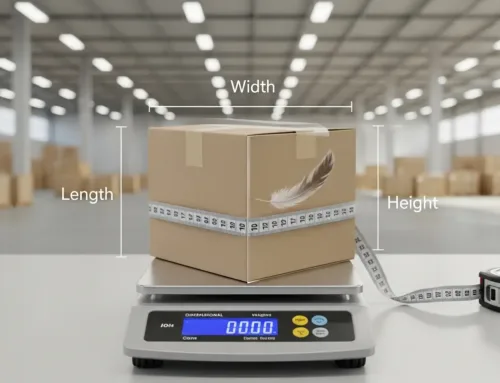

Before finalizing any product or packaging:

- Mock up the complete package — Product + retail packaging + protective materials

- Measure all three dimensions — Length, width, height at the widest points

- Calculate dimensional weight — Use the Dimensional Weight Calculator to see billable weight

- Compare across carriers — Different DIM factors mean different costs

- Evaluate alternatives — Can the retail box be smaller? Can you ship without it?

The Product Development Checkpoint

Smart brands build shipping cost analysis into their product development process:

| Stage | Shipping Consideration |

| Product design | Can dimensions be reduced without affecting function? |

| Retail packaging | Is this box necessary for shipping, or just display? |

| Supplier selection | Can the manufacturer ship in smaller packaging? |

| Pre-launch testing | What’s the actual DIM weight with real packaging? |

Retail Packaging: The Hidden Culprit

Many brands receive products from manufacturers in beautiful retail boxes—then ship those boxes inside another shipping box.

This “double boxing” dramatically inflates dimensions. Consider these alternatives:

- Ship in retail packaging only — Add shipping labels directly to retail boxes when durable enough

- Remove retail packaging for ship-to-home orders — Reserve display boxes for retail stores

- Design retail packaging to double as shipping — Corrugate-grade retail boxes that protect without an outer box

Calculating Your Potential Savings

Let’s put real numbers to these strategies.

Scenario: An ecommerce brand shipping 5,000 packages per month

| Optimization | Per-Package Savings | Monthly Impact |

| Right-sized boxes (avg 2″ smaller) | $0.85 | $4,250 |

| 30% of orders in poly mailers | $0.65 × 1,500 | $975 |

| Reduced void fill | $0.15 | $750 |

| Eliminated double-boxing on 20% of orders | $1.20 × 1,000 | $1,200 |

| Total Monthly Savings | $7,175 | |

| Annual Savings | $86,100 |

These numbers are conservative. Brands with bulky products or extensive catalogs often see even greater returns.

Make Optimization Automatic

Implementing these strategies across hundreds of SKUs and thousands of monthly orders is complex. It requires:

- Diverse box inventory

- Clear packaging guidelines per product

- Staff training on optimization principles

- Ongoing auditing and refinement

This is exactly what professional fulfillment centers do. At ShipCore, packaging optimization is built into every pick and pack operation:

- Right-sized box selection for every order

- Flexible packaging where appropriate

- Minimal void fill through proper box matching

- Multi-carrier rate shopping to find the best price per package

The result? Lower shipping costs without any sacrifice to delivery speed or product protection.

Your Next Steps

Packaging optimization isn’t a one-time project—it’s an ongoing practice. Start with these actions:

- Audit your current shipping data — Identify which products have the largest DIM gaps

- Test your bestsellers — Calculate the billable weight of your top 10 SKUs with our Dimensional Weight Calculator

- Evaluate box alternatives — Could 2-3 new box sizes eliminate most void fill?

- Consider flexible packaging — Which products could shift from boxes to mailers?

- Talk to a fulfillment expert — Contact ShipCore for a free packaging analysis

Every dollar saved on shipping goes straight to your bottom line. In a market where margins are tight and competition is fierce, packaging optimization is one of the highest-ROI investments you can make.

Frequently Asked Questions

How much can I realistically save with packaging optimization?

Most brands see 10-25% reductions in shipping costs from packaging optimization alone. Brands shipping bulky, lightweight products often save even more. Case studies show ROI ranging from $65,000 to over $260,000 depending on volume and current packaging efficiency.

Should I use custom boxes or standard sizes?

For high-volume SKUs, custom boxes often pay for themselves quickly through reduced shipping costs. For diverse catalogs, a well-designed library of 5-8 standard sizes provides flexibility while still minimizing void space.

Are poly mailers safe for shipping clothes?

Yes. Poly mailers are industry standard for apparel shipping. They’re water-resistant, lightweight, and durable enough for most soft goods. For premium brands, biodegradable paper mailers offer a sustainable alternative with similar protection.

What’s the best void fill for fragile items?

For fragile items requiring cushioning, paper-based alternatives like kraft paper or PaperBubble provide protection comparable to plastic bubble wrap while being fully recyclable. Custom foam inserts work well for high-value electronics or glass items.

How do fulfillment centers handle packaging optimization?

Professional 3PL providers maintain diverse box inventories and train staff on optimal packaging selection. Orders are matched to the smallest appropriate box, with packaging guidelines established per SKU during onboarding.

Ready to see how much you’re overpaying on shipping? Calculate your dimensional weight now and start optimizing today.